Why partner with us

-

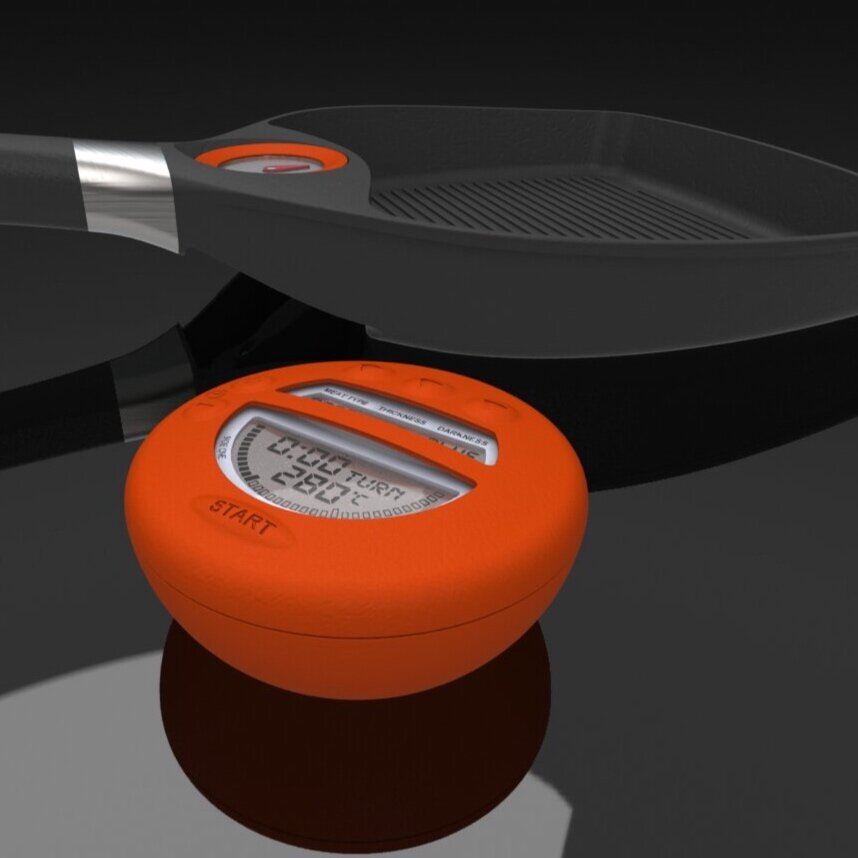

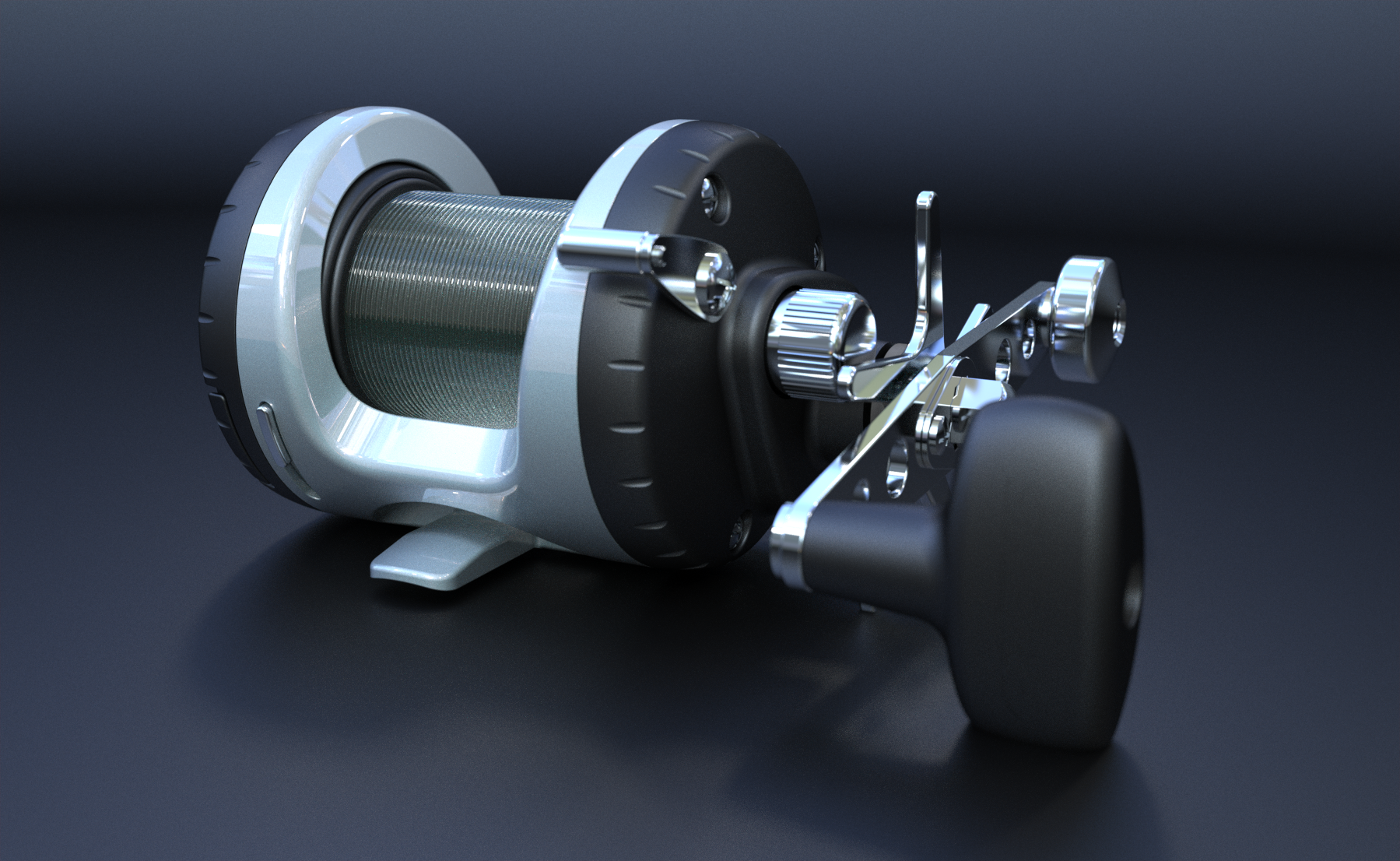

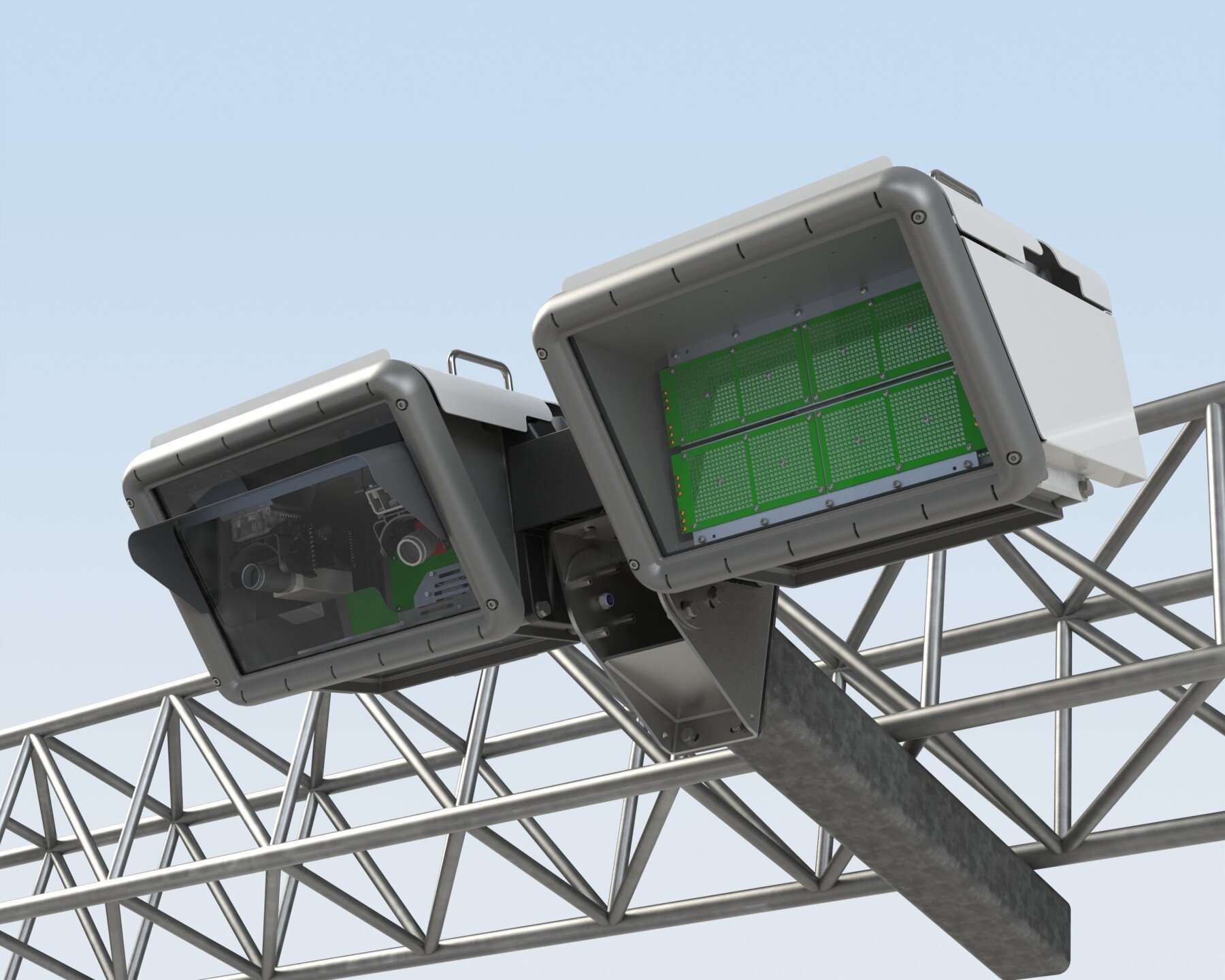

Our Client/Partners get a greater number of successful products faster with less stress. Our skills are in Problem-solving, patent busting, Innovation, Engineering, styling. We combine new product development with supply chain and manufacture. We deliver on time and on budget.

-

We work with a small number of clients each year and focus on creating successful products. While we are not inexpensive, we aim to provide value to our partners and prioritise forming mutually beneficial relationships. We will decline an opportunity if we can't add value or receive a return.

-

With over 40 years of consultancy experience across various industries, our expertise is unmatched. We focus on delivering solutions rather than merely providing options. Our seasoned professionals can quickly identify and implement effective strategies, ensuring your project's success. We prioritise making profitable decisions for our partners and uphold the highest standards of quality and efficiency.

-

Our approach is grounded in providing unbiased, honest opinions and ensuring our team remains on track to meet your goals. We are committed to delivering solutions that meet your needs without offering multiple confusing options. We believe in direct communication and will candidly inform you if an idea is not viable, saving you time and resources.

-

Consultants charge for time, not results. They want to spend as much time as possible and show as many options as possible.

Clients want a single solution.

Consultants will develop a clients bad idea because they are selling time not results.

We feel that the consultant is the expert and they should give the client the best result. If the consultant has a vested interest in the project they will ensure that the project is as efficient as possible.

This will reduce the time taken and best use their experience.

However, few projects have the funding required and the right relationship between consultancy and client to make this approach work.

There is a lack of differentiation among consultants and an overwhelming number. Most consultants show numerous products that they have worked on without clearly attributing their role in the process, making it hard to gauge their actual value.

As a result, the decision of who to use is often based on proximity, cost, and personal likability rather than expertise, leading to suboptimal outcomes.

Its not about the skills in the consultancy they will all have a similar skill set, CAD, FEA, Engineering, Prototyping.

It's the skill and experience your are buying. The truth is that the more skill an engineer gets he ends up managing. So a consultancy with staff under 30 will not offer the same skill set as staff between 40 and 60. We value experience and attitude

-

Silo Problem

Large companies employ specialists in departments or silos for efficiency and streamlined production. However, this silo structure limits knowledge transfer.

Company Development

A typical company structure includes a product manager, a development team, and a production team. This linear method tends to result in creating products that compete with similar ones in the market.

Risk

In this type of organisation, risk is neither encouraged nor rewarded. As a result, they fail to create disruptive products.

Conclusion

Companies are designed to improve rather than create new products, which is a short-term strategy. However, new products are essential to ensure future success.

New Product vs Incremental Improvement

Improvement is best done internally, while new product development requires a specialised team.

Solution

Excellent product development involves a combination of engineering, marketing, manufacturing, sales, materials science, electronics, software, ergonomics, UX, UI, research, and teamwork, with many significant decisions to be made.

The Trick - Decision Distance

The closer the collaboration between different disciplines, the better.

The elephant in the room

Design Talent, skill and attitude need to be recognised. It’s like sports: There are great managers and players who play for great teams and are valued and paid well.

If the stakes are high, you want the best!

-

Different-sized companies have varying needs and perceptions of consultancy:

Multinationals: Have in-house teams but use external consultants for overspill or specialised research.

Medium-sized Companies: Often view consultants as expensive and prefer in-house solutions.

Small companies: Frequently forced to use consultants but aspire to develop in-house capabilities.

In-house teams, especially those with recent graduates, may need more experience and breadth of skills that seasoned consultants offer. While in-house engineers and designers grow into their roles, they may not have the necessary skills for innovative new product development, which requires a different mindset and extensive experience in managing risk and making critical decisions quickly and effectively.

The Role of PG in a Partnership

Our role extends beyond that of traditional consultants; we act as multidisciplinary engineers, designers, mentors, and partners. Our extensive experience enables us to handle every aspect of the development process, providing unparalleled expertise that in-house teams or less experienced consultants cannot match.

-

We offer a unique, high-value service that is highly effective when used correctly.

Our services are not a good fit for individuals, inventors.

Our revenue models include - Fees, Bounty, Licence / Royalty, Sourcing, Manufacture, Assembly, and Supply.

We prioritise projects with significant financial potential, ensuring mutual profitability.

Ideal Partners

We seek well-funded partners who understand their needs, appreciate the value and difficulty of the deliverables, and can effectively market the final product.

In summary

Partnering with us provides a strategic advantage through our unmatched experience, focused solutions, and commitment to your success.

Part 2 of a conversation with Lou Street a product development and procurement specialist. Lou and I have worked on many projects together. We discuss all aspects of developing new products with Chinese factories, how to save time, money and de-risk the process. We cover developing a specification, finding the partner factory, developing prototypes, costs for tooling, first build, QC & Testing.